REDWOOD LOGIN

Redwood PortalLTL

SCS

SCS Support

Rockfarm

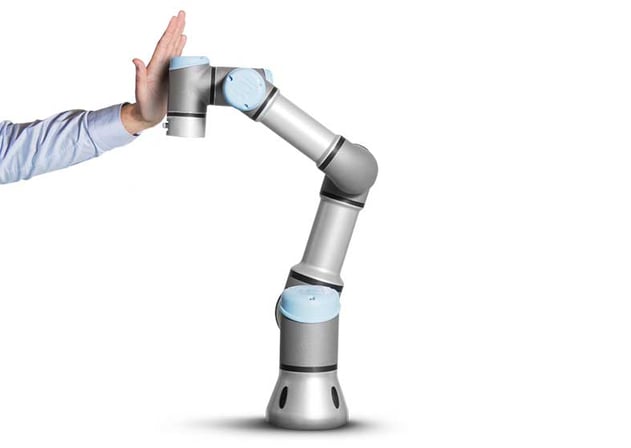

A collaborative robot, commonly known as a cobot is any robot that has the Cicapacity to learn how to perform specific functions in order to assist people in a variety of tasks. The term was coined sometime back in the mid-’90s.

At that time, most robots that were being used in industrial work were rather large and were being used to perform repetitive tasks in fairly well-controlled environments. More often than not, there were very defined protective barriers set up to keep workers out of the vicinity of the robots where they might otherwise be injured by the moving machinery. It was also around this time that better processing power and sensor technology was just starting to be heavily researched, applied, and tested in real-world scenarios.

These moving, task-oriented robots quickly became known as cobots…

Fast forward to 2019, and you can see that things have changed quite a lot. Nowadays, there is more thorough research being done into artificial intelligence and it is fueling some really neat technological innovations. This has led us to some pretty drastic changes in how we interact with our gadgets.

Today, cobots see most of their use taking place in warehouses and other industrial operations where they facilitate roles in order to increase efficiency, operating speeds, and free up workers for other tasks… or, all of the above.

And best of all, thanks to advances in sensor technology and situational awareness, cobots now frequently work right alongside human workers.

One fear that people have when you start telling them that they should place working robots in their warehouse is that, somehow, the robots will rise up and take over all the human jobs. This could not be further from the truth.

Cobots are not designed to replace human workers, they are created with the intention of augmenting that worker’s capabilities. If you were to google the word cobot right now, I can almost assure you that you will find some pictures of robotic arms. This is probably one of the most common examples of a cobot being used along an assembly line.

Well, that arm doesn’t take away from the human worker being able to do their job, it actually gives them an extra hand to work with. This not only can double the speed of the task being performed, but it can also help minimize the risk of mistakes that are attributed to simple human error.

Besides, who couldn’t use an extra hand at work?

If we haven’t yet convinced you that investing in a cobot is a good idea, let’s talk about what areas of your operation are going to benefit the most from jumping on the cobot bandwagon.

For starters, I will tell you that depending on what type of cobot you are considering buying for your warehouse, it is going to be a rather large investment. Yes, you heard me correctly… an investment.

Most commercially viable options that would benefit medium to large warehouses available at the moment are going to start somewhere in the thousands and can cost as much as hundreds of thousands.

Now before you start scoffing at the prices, just check out the top 2 ways a cobot can benefit your warehouse operations…

Pick and place tasks are very tedious ones that most human warehouse workers absolutely despise having to complete. It is boring, repetitive, and just downright lackluster. And that is not to mention that constantly turning or twisting in the same direction over and over again throughout the day can easily cause strain to muscles and even painful injuries.

Pick and place roles are any tasks that require an item to be picked up and placed elsewhere. This could be anything from transferring items from one conveyor belt to the next to sorting out items into individual groups and placing them into containers.

If any of your workers are worried that your new cobot is going to take their job from them, simply remind them of the pick and place station.

Since this is not a desirable position for most people, it serves as an excellent testing ground for a first-time cobot owner or operator. Here you can test out its skills and safely learn how to operate it without completely bringing your business to a screeching halt by testing it on more crucial processes.

And if it is a good fit, your employees will thank you, and you will be getting the job done much faster than any human could do it manually.

Similar to pick and place tasks, packaging is another fairly repetitive job for most humans. Especially box assembly…. Oh man, do people really hate putting boxes together!

Aside from assembly, the boxes may need to be shrink-wrapped or placed and secured onto a pallet. These are things that some larger cobots may be able to handle for you.

In both pick and place and packaging, you would need to make sure you invest in a cobot that has a built-in vision system to identify products of various shapes, sizes or colors. A vision system is simply a program that is coded into your cobot in addition to some sensors to read specific data about an item it has grabbed with its end-effector. And if you are using a cobot on a conveyor built then it may also require some additional programming to allow it to synchronize its robotic arm movements with that of the conveyor belt.

Cobots are extremely beneficial tools that can skyrocket your warehouse operation speeds while lending an extra hand (or two) to all your human workers.

With technological innovation happening every single day and the interest of the IoT in the logistics space growing at an almost alarmingly fast rate, cobots are getting better at what they do.

Thinking about installing a collaborative robot in your warehouse? Before you do, shoot us an email and let us give you a few personalized recommendations!