REDWOOD LOGIN

Redwood PortalLTL

SCS

SCS Support

Rockfarm

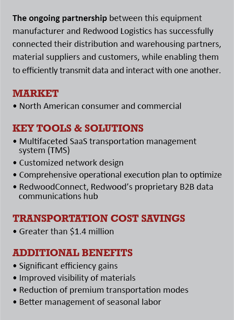

The company at the center of this case study is a family-owned, Wisconsin-based manufacturing company that develops, manufactures, and distributes outdoor products and parts for the consumer and commercial markets.

Established in 1933, the company maintains seven major brands and is well known for its lawn tractors and snow throwers.

After Redwood Logistics was chosen as its logistics and freight management partner, the company sought to maintain its lean manufacturing approach to inventory, while improving its distribution efficiency, delivery performance, and forecast model.

Redwood’s mission was to optimize distribution costs between its production facility in Wisconsin and its five warehouses while managing inbound deliveries from more than 250 different suppliers. Additionally, Redwood was tasked with integrating data across the SaaS TMS (transportation management system), their internal systems, multiple suppliers and third-party service providers.

With deep expertise in the transportation management life cycle backed by a knowledge services team with experience in network design and the application of technology to logistics business process, Redwood Logistics associates designed a customized transportation management and technology solution.

Redwood implemented a powerful SaaS TMS and leveraged TMS.io, Redwood’s proprietary B2B communications hub, to manage their inbound and outbound shipments and orders. Redwood’s customized solution gives them the freedom to continue using its existing third-party warehousing providers for its regional warehousing requirements.

The ongoing partnership with Redwood Logistics has successfully connected their distribution and warehousing partners, material suppliers and customers, enabling them to efficiently transmit data and interact with one another.

The best of breed, fully integrated production and distribution infrastructure designed by Redwood allows them to anticipate and prepare for demand fluctuations throughout each season and the calendar year. Redwood’s data-driven, integrated solution has produced concrete results during its first year.

The exchange of supply chain data facilitated by Redwood Logistics’ solution brings them the deep business intelligence and operational efficiency that it had been seeking in a 3PL provider for several years. The result is cost savings through innovative approaches to delivery, such as breaking up truck loads for certain locations to decrease cost per delivered pound.

Redwood Logistics has formed a solid partnership built on accurate inventory and efficient freight management, which ultimately benefits all parties involved — from their operations in Wisconsin to their warehouses, distributors, and retail customers across North America. In the future, they will be seeking further support and guidance from Redwood as its business continues to grow, and as the company realizes even greater efficiency gains from Redwood‘s integrated logistics solution.